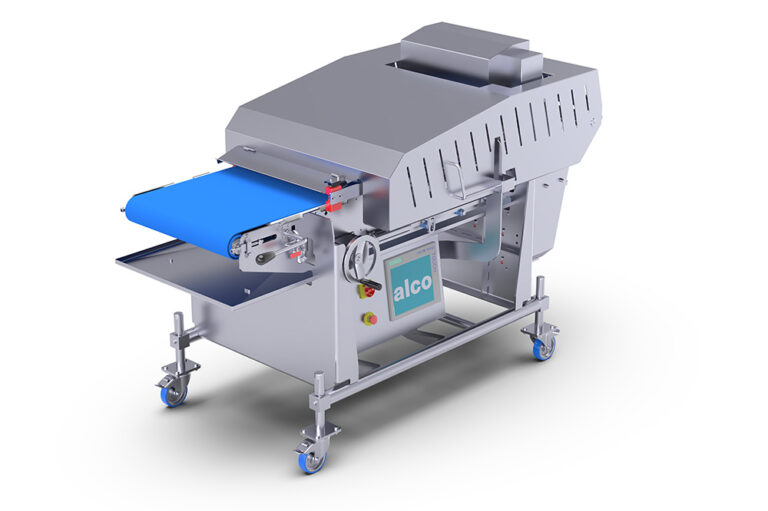

Manual belt height adjustment for adjusting desired product thickness

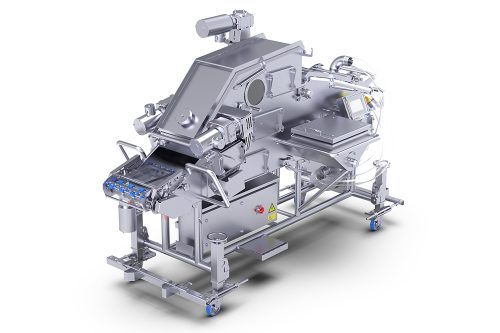

Flattening area with pressing/stretching roller pairs

Outlet hold down belt optimally transfers the product to downstream equipment

Flattening Machine ASP

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

JBT alco Flattening Machine ASP

The JBT alco Flattening Machine ASP flattens fresh and tempered frozen meat. Through its its unique feature, the machine guarantees individually set product thickness for all suitable products with low memory effect. The desired product thickness can be defined in advance by hand, through a height adjustment, ensuring your product meets all your requirements.

The innovative machine uses rubberised drive rollers to prevent belt slipping and utilises a fine water spray bar to prevent protein build up on the belt, ensuring a perfect product transfer through a pivotable outfield belt. There is also a collection tray for product residues, ensuring a clean-floor policy to maintain a hygienic production room.

Optional extras include additional belts to carefully adjust the product through the flattening process and extended infeed area providing additional space for preparation.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment