Batter curtain with overflow devices

Adjustable blower system removes excess coating for consistent results

Adjustable pump system adapts to liquid viscosity and ensures complete coating on all sides

Integrated material return system

Operator-friendly touch panel control

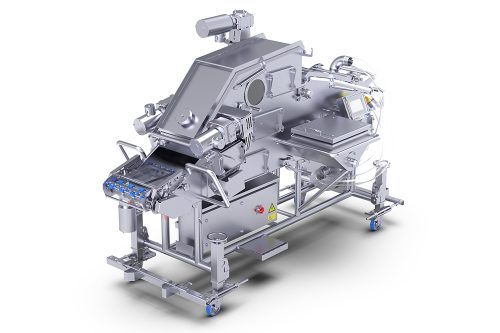

Battering Machine APN

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

JBT alco Battering Machine APN

With suitability for various applications, the alco Battering Machine APN coats your products completely, ensuring even application on all products. In the case of excess coating, there is an adjustable blower system and integrated material return system, minimising waste, while guaranteeing optimal coating. The machine applies liquid materials of various viscosities and is suitable for meat, poultry, fish, vegetables, cheese and plant-based products.

Made entirely of stainless steel and food-approved plastic, the design is easy to clean and maintain. The machine also ensures high operating safety with an intuitive operation through an interactive touch screen.

There are also opportunities to improve this machine with additional features to enhance operation and food safety. A cooling jacket provides the ability to cool and maintain the coating material temperature to ensure food safety. A high-speed product belt allows for belt speeds of up to 29 meters per minute, permitting high throughputs.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment