Innovative coating material distribution

User-friendly touch panel control

Optimised drum with variable speeds for various throughputs

Clump filtering and blower air circulation system

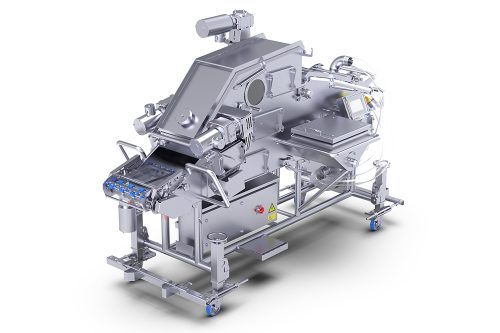

Drum Breader ADB

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

JBT alco Drum Breader ADB

With the Drum Breader ADB, JBT alco has developed a superior breading-flour distribution and sprinkling system, ideal for hard-to-coat products. Its versatile design caters for a range of crumb size, from fine to coarse in continuous operation. Delicate and complex shaped food such as prawns can be fully covered with a combination of pre-coating and a gentle tumble action that preserves their shape and quality. An integrated clump sifting system ensures an even coat to all products. With a hygienic design for top product safety, the machine is also easy to operate and clean.

An optional lateral supply and refill funnel allows for ergonomic and automatic equipment filling, removing this manual task from the operator, ensuring time is maximised during the processing procedure. A suitable accessory may be the crumb feeder, which is responsible for automatically filling the drum reader with the coating material. An additional dust-free system collects up the resulting dust from the plant and transfers it into a separate system container, ensuring a cleaner, more hygienic option for the production room.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment