Rotating filter for large residue removal.

State-of-the-art technological fume-extraction systems.

Stainless steel construction with thick insulated panels to prevent heat dispersion. This dual-function technology reduces energy consumption and noise.

Mechanical system for raising the top part of the tunnel, allowing simple cleaning, maintenance, and inspection.

Pallet Washing Systems

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Colussi Ermes Pallet Washing Systems

Innovation and organisation to guarantee competitiveness, and flexibility and quality for absolute environmental protection.

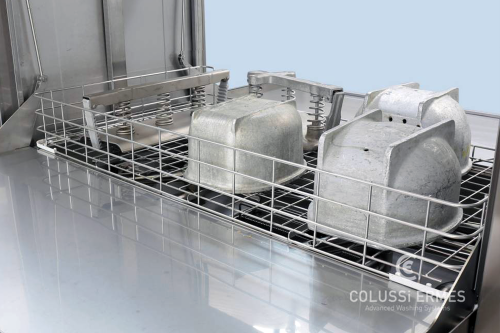

With over 50 years of experience, research, and innovative development, Colussi Ermes has manufactured thousands of washing systems that produce the highest level of performance for processors throughout the world. Innovative design, rounded shapes, accurate details, and high efficiency: a tailor-made concept to address a variety of complex requirements and produce solutions that ensure optimum results. The Pallet Washing systems are designed to facilitate factors including available floorspace, production capacities, the type of residue/soiling to be processed, power supply, and reduction of energy consumption.

The tailor-made pallet washers are fully automated and manufactured according to extremely high-quality standards which, thanks to particularly high-pressure systems, are able to eliminate even the most stubborn dirt and residue.

The advanced systems facilitate responsible dosing of chemical solutions for both operator safety and environmental protection. With consistent monitoring of the functions and critical parameters, the systems featuring state-of-the-art technological systems for the extraction of fumes, innovative filtering systems for continuous removal of residue produced by the washing cycle.

- TAILOR-MADE: the machine is designed, developed and configured for each individual customer, on the basis of their requests and requirements.

- Structure in stainless steel with thick insulated panels to prevent the dispersion of heat produced by the pallet washing process. This technology offers a dual function: reduction in energy consumption and noise reduction.

- Customized washing programs.

- Washing programs designed to obtain maximum energy efficiency.

- High pressure to remove all types of stubborn residue or dirt.

- Advanced systems for the removal of water residue from the surfaces of the benches.

- Responsible dosing of chemical solutions to protect the environment as well as the operators involved in the pallet washing operations.

- Multiple water heating systems.

- Significant savings of energy, water and detergent.

- Reduction in maintenance costs and times.

- Reliability and performance levels unchanged over time.

- Constant and uninterrupted monitoring of the functions and critical parameters.

- Interfacing with centralised monitoring systems compliant with HACCP standards and automatic feed systems of the equipment to be washed.

- A special mechanical system allows the top part of the tunnel to be raised allowing easy cleaning and maintenance operations and full inspection.

- Structure in stainless steel.

- Prime quality raw materials.

- Selection of materials responding to extremely high standards (pharmaceutical).

- State-of-the-art technological systems for the extraction of fumes.

- Innovative filtering systems.

- Rotating filter for the continuous removal of large residue produced by the washing cycle.

- Pre-wash cycles for eliminating the most stubborn dirt and residue.

- CIP (Clean In Place) self-washing program which for preserving and purifying the production line of organic and inorganic contaminants. CIP is a self-washing automatic system for all circuits, walls and key points of the machine which does not require disassembly. This is carried out through the introduction of detergent fluids at a specific pre-set concentration, pressure and temperature and constantly monitored, followed by careful washing and sanitization.

- Drying system using a new technology designed and developed by Colussi Ermes able to combine optimal drying capacity with minimum consumption. Pallet drying with traditional or centrifugal methods.

- Constant monitoring of all parameters in compliance with HACCP standards (Hazard Analysis and Critical Control Points). This program allows the operator to have full control of the critical points to ensure hygiene.

- Automated movement, stacking and destacking systems, including loading and unloading.

- “Ready to Use” program for immediate system operation at the start of the shift.

- Removal of adhesive labels.

Pallet and flatted washing systems, customised to meet any requirements or technical/production demands:

- Small cabins with a single door which offer ad hoc washing cycles for limited quantities of pallets, ensuring maximum hygiene safety standards.

- Medium sized cabins with a single door or double doors, stand-alone or in-line, to wash larger quantities of pallets, also with a centrifugal system.

- Large-scale innovative high-tech multi-phase tunnels, for industrial use, suitable for hourly washing cycles of up to 300 pallets/hour. This amount can be easily doubles by adding a second machine.

The Colussi Ermes range of industrial pallet washing systems are suitable for sectors including:

- Meat

- Poultry

- Fish

- Dairy

- Fruit & vegetables

- Confectionery

- Logistics

- Pharmaceutical

- Automotive

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment