From the highly automated line concept for snacks and convenience products to the efficient automation concept for fresh meat applications – Weber will be presenting its wide, in-house of range solutions once again at IFFA.

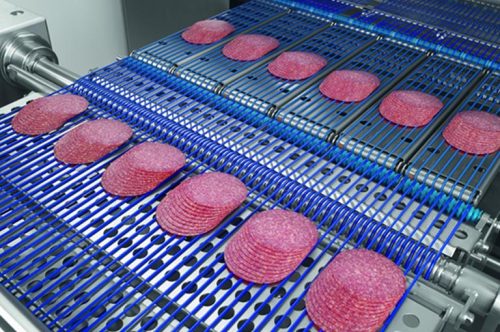

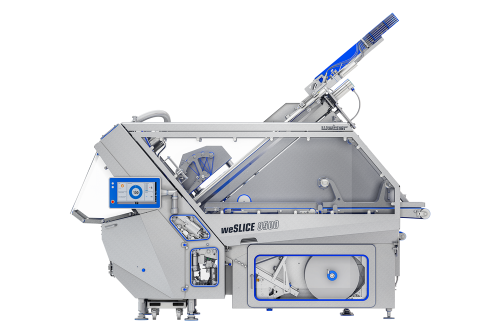

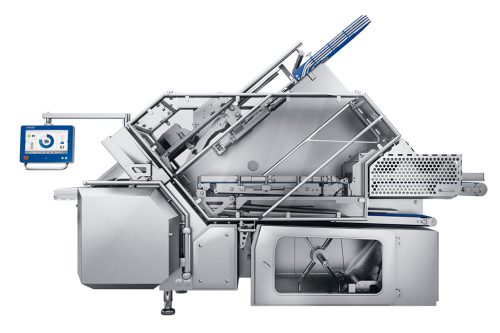

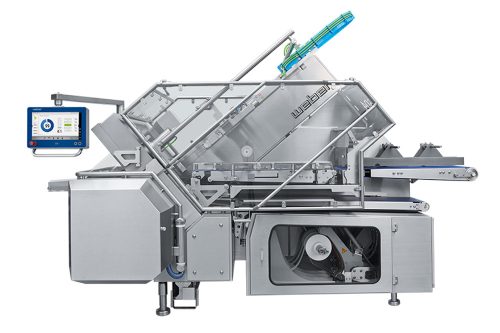

As the market leader for full solution lines in the area of slicing applications, Weber is known for its integrated processing and packaging concepts. However, at the IFFA in Hall 12.1 Stand A01, visitors will be able to see for themselves that our wide range of solutions and services has far more to offer and that Weber customers can expect this “plus” from us in many respects as a system supplier and partner. In addition to an efficient and simultaneously high-performance full solution line for caliber goods such as deli meat, salami and ham, visitors can also look forward to a line for processing and packaging raw ham in an exciting packaging concept. One of the highlights at the Weber stand will be a line solution for the production of snack packs with cheese hearts, mini salami slices and olives in olive oil. The heart of this innovative processing solution is the Weber weSHUTTLE transport system. Characterized by maximum flexibility in terms of application variety and spatial design options, line solutions centered around the weSHUTTLE can be precisely tailored to customer-specific recipes. Where other systems have limitations, this unique automation solution enables the implementation of applications and requirements that could not otherwise be realized – a real game changer.

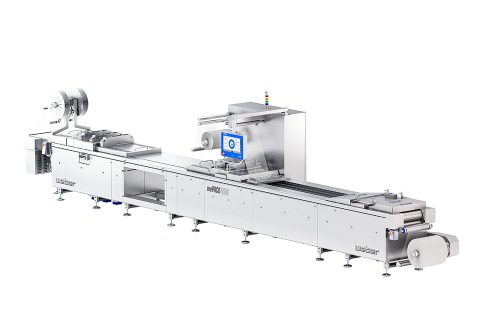

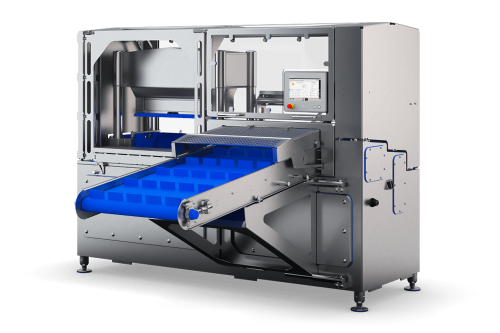

Precise portioning and packaging of fresh meat in high performance ranges is an especially demanding challenge. At the IFFA, Weber will be presenting a solution that masters this challenge with flying colors. This is made possible by the high-performance Weber components ranging from the wePRESS press to the wePACK thermoformer packaging machine. The highly automated solution allows maximum outputs of fresh meat applications such as minute steaks or shabu-shabu to be realized in a weight-accurate manner – and on an especially compact footprint at the same time.

Fully exploiting the potential of this first-class technology and thus increasing overall system effectiveness as well as uptime while reducing operating costs also requires the intelligent networking of all line modules and the recording and convergence of all relevant data. A special focus will therefore also be on the digitization of food production using the wide range of digital Weber products and services.

The Weber Skinner team will also be showcasing many innovations in a portfolio that has been revised in line with the market for trade, medium-sized companies and industry at the IFFA. The wide range of solutions for meat processing have also been upgraded especially in the areas of safety and hygiene. Visitors can expect, for example, the new ASB 560 industrial belt derinder, which impresses with the best product yield and minimized post-processing thanks to the unique Weber front slice automation.

In addition to technical solutions, the Weber Skinner team also supports customers with their unique expertise in the areas of personal consultation, individual needs analysis and competent service with fast spare parts availability. For more than forty years, Weber has been the absolute specialist when it comes to derinding, skinning and degreasing red meat and poultry as well as one-dimensional slicing of meat slabs and slices.

About the Weber Group

From weight-accurate slicing and packaging of deli meats, fresh meats, cheese and vegan products to complex automation solutions for ready meals, pizza, sandwiches, and other convenience products: Weber Food Technology is one of the leading system providers for foods such as sliced products and piece goods as well as the automation and packaging of fresh products. The company’s main objective is to make life easier for customers by providing outstanding, customized solutions and enabling them to operate their systems optimally throughout the entire lifecycle.

Around 2,100 employees at 27 locations in 22 countries work at Weber Food Technology and contribute to the success of the Weber Group every day through their commitment and passion. To this day, the company is family-owned and managed by CEO Tobias Weber, the oldest son of company founder Günther Weber.

The Weber Food Technology range is available in the UK from Interfood Technology’s dedicated Slicing and Packaging Line Solutions Division. Talk to our experts to find out how we can take your operation to the next level.

DISCOVER THE WEBER FOOD TECHNOLOGY RANGE