Weber Modules

Weber and Textor slicers can be specified or upgraded in the future to include a wide choice of modules and ancillary equipment that will enhance efficiency and performance. These can be easily integrated to provide individual solutions to meet your specific needs.

Weighing

Weight Control

A range of checkweighers and diverting systems integrated into the slicing line to provide high accuracy portion control. Incorporating feedback to the slicer and portion tracking systems enabling individual portions to be highlighted for correction without removal from the slicing line creating optimum efficiency.

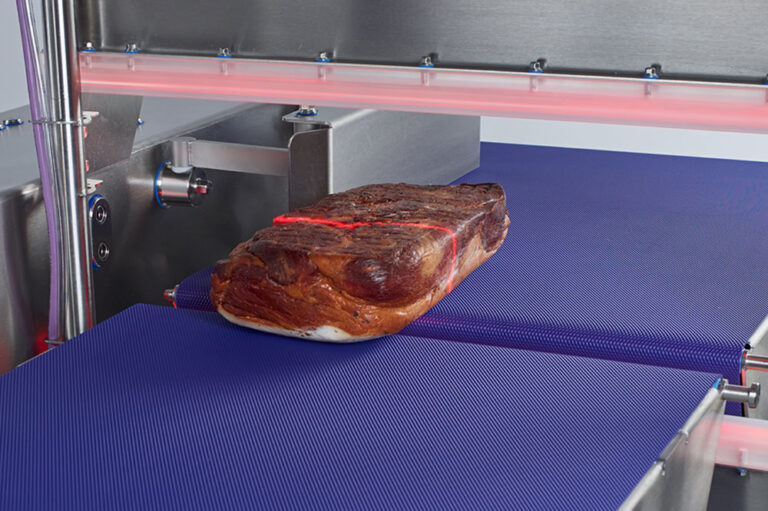

Scanning

Scanning Proactive Control

Either via a separate module behind the slicer or integrated via the on board "smart scanner" available on the Textor TS750 Slicer. Scanners are available with the latest LED illumination technology or X-ray for products with internal cavities such as continental cheeses. Available in mono or multiple lane execution and up to 750mm wide and 1200mm long depending on the application.

Presentation

Portion Designer

Interleaving/Underleaving

SprayTech

A wide range of product designs are possible for shaping, spreading or mixing portions or platters. Overlapping, side shingles, rounds, oval and bespoke shapes are a few of the limitless possibilities.

Fast and efficient insertion of plastic, parchment, paper or recyclable film either in-between individual slices or underneath the complete portions. This maintains the integrity of delicate, thin-sliced, high-value products and assists when ease of separation is required.

Weber SprayTech is a potential sustainable alternative to interleaving with film or paper. Typically utilising a tasteless, odourless non-stick agent such as rapeseed oil. Suitable for a wide range of products, from highly adhesive, sticky products such as cheese or vegan products, to shaved applications or cooked ham. SprayTech can be fully integrated into all current and existing Weber and TEXTOR slicers. The technology can also be used to add flavourings and is under development for the use with bio-protection materials to enhance product safety.

Blade Technology

Durablade

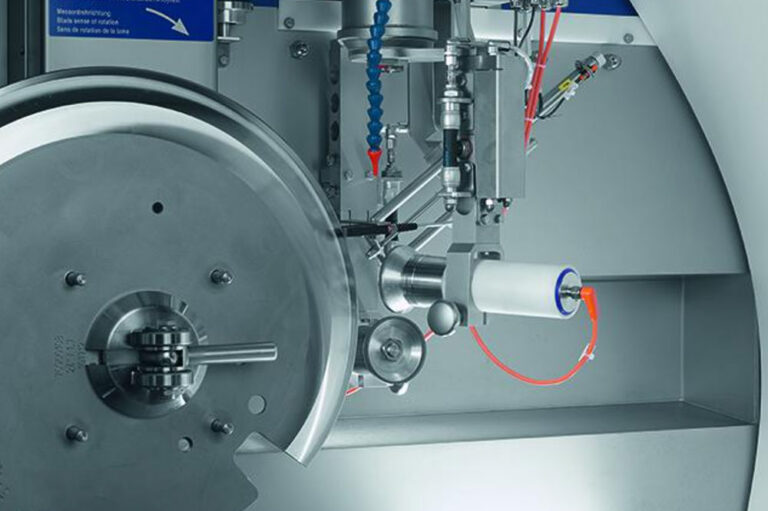

Blade Sharpening WeSHARP 7000

Manufactured in Weber’s own blade factory with a heavy emphasis on research and development, the Weber circular and involute blades are marketed worldwide under the Durablade brand.

Made entirely of stainless-steel with a composite hardened edge, which is the ideal combination of materials to maintain hygiene, quality and performance.

The weSHARP sets new standards in onsite blade maintenance for both round and involute blades. With integrated features to automatically recognise and inspect the knife prior to sharpening. The correct process is always assured and the blade condition is both monitored and recorded taking the emphasis away from the user to manage blades within the factory.

With driven stones which give short sharpening times and a repeatable finish to the cutting edge.

Smart Operation

Weber Power Control

The award-winning Weber Power Control is the latest operating system from Weber, utilised across all modules, it uses intuitive dashboard functionality much like most modern smartphones. This makes it easy to use and instantly familiar to operators.

Vario & Vacuum Grippers

Products of differing sizes and lengths can be fed towards the blade independently, either reactively according to checkweigher feedback or using pre-slice scan data. Available in up to four independent tracks to enable optimum accuracy, yield recovery and efficiency.

The Weber developed hygienic vacuum gripper system, is ultra-efficient in terms of air consumption and depending on product, can offer up to 50% reduction in gripper end size.

PREPARATION

Peeling Machine

The Log Peeler CCP automatically fully, and hygienically, removes the outer casing from lunch meats and cheese products. As hygiene is of the utmost importance in food processing, the Log Peeler recognises and inputs a clear distinction between grey zones and hygiene zones, allowing the product casing to remain in the grey area, which increases the sanity and safety of the peeled product.

Weber weDIVIDE

weDIVIDE Weber cheese block divider is the perfect start for a productive and highly automated line. Fully integrated or stand-alone, the weDIVIDE divides both UK and euro block formats into the required bar size, automatically adjusting the cut size to maximise yield recovery and line efficiency.

ENQUIRY