Quick disassembly/ reassembly for cleaning with robust, quick-release fittings.

Compliant with HACCP protocols and food safety requirements.

Easily integrates into your existing rigid or flexible pipe system.

Iris

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

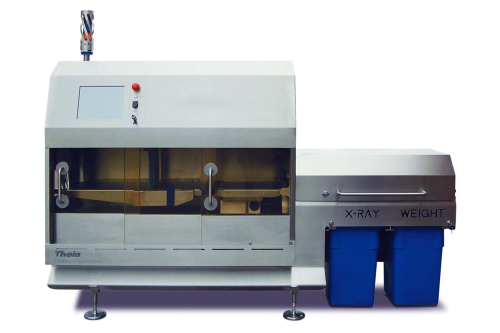

Sparc Systems Iris Pipeline X Ray Inspection System

Typical applications of the Sparc Systems Iris pipeline include whole muscle products such as chicken breasts, ground meat, pie fillings, soups and sauces, fruit and vegetables and even ice cream. The three models of the Iris product range include the 1.5-inch, 2.5-inch and 6-inch, which are all designed to swiftly and simply integrate into your existing rigid or flexible pipe system.

The robust quick-release fittings allow for a quick disassembly and reassembly within a matter of seconds, ensuring the fastest assembly time possible. This design also allows for a simplified and easy-to-clean system, ensuring maintenance and sanitation is easily accessible and therefore increases the longevity of the machine.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment