Compliant with all existing COP’s as standard with full reject integrity functionality.

In-line, servo-driven reject system provides fast and accurate rejection into a dedicated lockable reject station

Can be supplied with integrated data collection software for live OEE reporting.

Tool-free cleaning with quick release connections and belts for minimum downtime.

Apollo

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

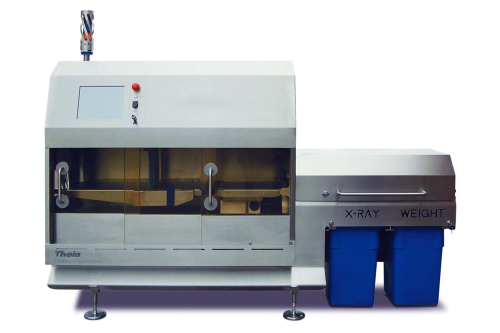

Sparc Systems Apollo X-ray Inspection Production System

Engineered to the highest standards, the Apollo achieves fast and accurate rejection of out-of-tolerance or contaminated packs into a dedicated lockable bins with the in-line, servo-driven reject system. This system eliminates the requirement of compressed air, which in turn, offers the possibility of reducing running costs, allowing the machine to work at its maximum efficiency at the lowest cost.

The Apollo can be equipped with integrated data collection software to provide instant live OEE data, reporting directly to production and QA personnel. It is compliant with current existing COP’s as standard and offers full reject integrity functionality. The machine also has a hygienic design as the cleaning process does not require tools for dismantling as there is quick release connections and belts. This also ensures a clean, hygienic machine that is fully safe for all food products during production.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment