Full reject integrity function at up to 200ppm.

Servo driven reject system provides superior performance and repeatability.

Live production and QA reporting, and batch information with integrated data collection software.

Fully-compliant with HACCP and retailer COP requirements as standard.

Calculated giveaway delivers control feedback upstream to portioning equipment, signalling required increase or decrease in filling quantities.

Cerberus

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

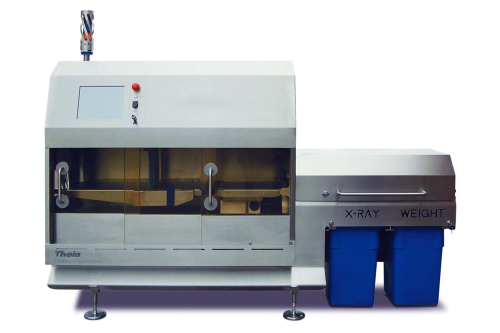

Sparc Systems Cerberus Metal Detection Inspection & Checkweighing System

Cerberus can incorporate SparcEye, the fail-safe top and bottom label inspection system from Sparc Systems that ensures retailer quality compliance and provides additional brand security. It ensures every pack has been inspected, the correct labels have been applied and every character on the date code, batch number etc is correct and readable. Fast and accurate rejection of out-of-tolerance or contaminated packs are securely put into lockable bins by using an in-line, servo driven reject system which removes the need for compressed air.

The average finished weight variance (giveaway) is also calculated which can deliver trend control feedback upstream to the portioning equipment with a signal to increase or decrease the fill quantity. With operating speeds up to 200ppm, Cerberus negates the need for manual checking and unnecessary labour costs while accurately performing all of the vision checks in a fraction of the time when fitted with SparcEye vision inspection systems.

Cerberus can be supplied with integrated data collection software to provide instant live OEE data and downtime reasons, reporting directly to production and QA personnel. It is compliant with all major retailer COPs as standard and offers full reject integrity features at up to 200ppm.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment