Automatic Feeder SHR 500-600

Padovani Technology

The Automatic Feeder SHR 500-600 from Padovani Technology is an innovative solution designed for small moulding machines. This automatic feeder receives dough from the mixer, breaking it into small pieces and transferring it in precise quantities to the hopper of the rotary machine and/or hard biscuit lines.

The feeder is equipped with a high-precision laser beam photocell for precise dough level detection. Users can adjust both the minimum and maximum dough levels in the hopper. When the dough hits the maximum level, the feeder stops until it falls below the minimum level. The feeder will then restart, ensuring a continuous dough supply.

For simplicity of operation and adjustment, the electrical panel is fixed to the rear of the device, complete with essential components such as the main switch, isolater, start/stop button, and emergency stop button, ensuring smooth operation at all times.

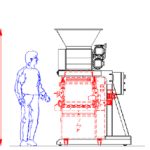

Constructed from stainless steel AISI 304 with a fork structure, this feeder is built to last.

Equipped with wheels for easy handling (two fixed wheels and two pivoting wheels).

Wide capacity stainless steel AISI 304 hopper, easily removable to facilitate cleaning.

EXPERT OPINION

James Fitch

Divisional Manager – Bakery

“The Automatic Feeder SHR 500-600 from Padovani Technology ensures a steady dough supply by accurately detecting dough levels and adjusting feed automatically. This feeder guarantees reliability, efficiency, and consistent product quality, making it indispensable for bakeries of any scale. Contact us for more information.”

ADDITIONAL PRODUCT INFORMATION

Automatic Feeder SHR 500-600

Code | Useful Width [mm] | Installed Power [kW] | Packaging dimensions (aprox.) [mm] | Gross Weight [kg] | Hopper Capacity [litri] | Highness from the ground [mm] |

|---|---|---|---|---|---|---|

SHR 500 | 500 | 1,5 | 1500 x 1000 x H2100 | 250 | Approx. 100 | 2150 |

SHR 600 | 600 | 1,5 | 1600 x 1000 x H2100 | 300 | Approx. 120 | 2150 |

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment

BAKERY

Dropping Machine

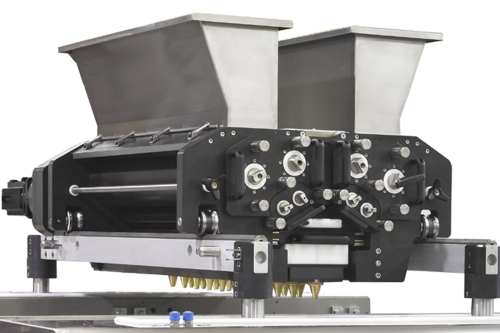

The Dropping Machine from Padovani Technology is designed to create biscuits using 1, 2, or 3 coloured doughs, offering maximum versatility for biscuit manufacturing. This model encapsulates all the characteristics of the 3-colour extruder, this machine allows for both horizontal and vertical manipulation of the extrusion head.

BAKERY

3 Colour Extruder

The 3 Colour Extruder from Padovani Technology is a reliable solution tailored for the production of tri-coloured filled biscuits. This technology facilitates the creation of biscuits with diverse shapes and colour combinations, offering versatility and efficiency for biscuit manufacturing operations.

BAKERY

Extruder

The Extruder from Padovani Technology is a specialised solution for biscuits with soft centers. With its specialised design, it ensures exceptional results in every batch. Available with a variety of accessories for decoration, including decorating rollers for texturing and flattening rollers.

BAKERY

Automatic Feeder Industrial

The Padovani Technology Automatic Feeder for Industrial Operations is engineered to automate dough loading processes across rotary moulding machines, sheet forming machines, and extruding machines. From the initial unloading of dough from the mixer to the feeder, every step is managed to ensure precision and consistency.

BAKERY

Automatic Feeder SHR 500-600

The Automatic Feeder SHR 500-600 from Padovani Technology is an innovative solution designed for small moulding machines. This automatic feeder receives dough from the mixer, breaking it into small pieces and transferring it in precise quantities to the hopper of the rotary machine and/or hard biscuit lines.

BAKERY

Rotary Cutting Machine

The Rotary Cutting Machine from Padovani Technology offers precise and efficient forming and cutting for hard biscuits. This advanced equipment is designed to emboss and cut various sheeted doughs into perfectly shaped biscuit forms, providing exceptional performance, reliability, and user-friendliness.

BAKERY

Laminator

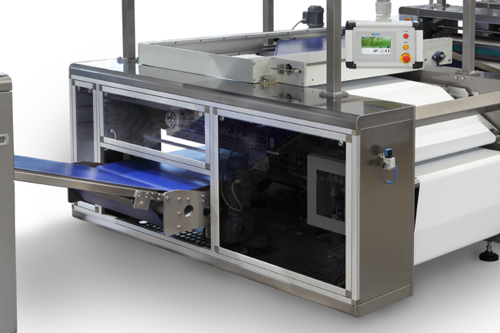

The Padovani Technology Laminator provides bakers with a flexible tool for producing layered doughs essential for various bakery items like pastries and croissants. Engineered to delicately layer dough with precision, the Laminator achieves the signature crispy, flaky texture found in high-quality baked goods.

BAKERY

Sheeting Lines

Sheeting Lines from Padovani Technology are versatile systems designed for precision and efficiency in producing sheet dough for hard sweet biscuits and crackers. Designed to accommodate a range of dough viscosities and textures, this system ensures consistent, uniform, and hassle-free sheeting.

BAKERY

Rotary Moulding Decorating Devices

Padovani Technology provides a comprehensive selection of decorating devices, specially designed for integration with their Rotary Moulding machines. These devices provide biscuit manufacturers with unmatched flexibility, allowing them to tailor their products to meet the diverse preferences of consumers.