3 Colour Extruder

© Padovani Technology

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

3 Colour Extruder

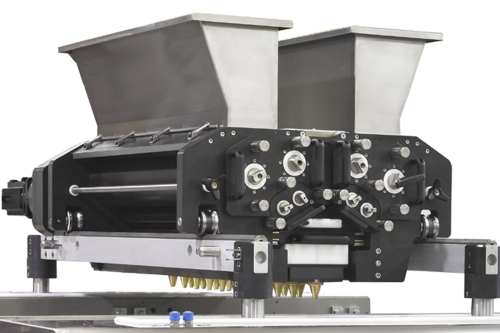

Advanced Extrusion System

The extruder features an advanced extrusion system powered by lobe pumps with separate compartments. This technology enables the creation of biscuits in various shapes while allowing the simultaneous use of up to three different colours of dough. This versatility opens up endless possibilities for creating visually striking and unique biscuit designs.

Precision Extrusion Heads

Designed to offer consistent performance and uniform results, every extrusion head is meticulously crafted. These heads are equipped with specialised components, such as a dedicated dough hopper, grooved rollers for efficient pre-loading, and a lobe pump with separate compartments. This carefully engineered configuration ensures smooth and reliable operation, allowing users to easily produce the desired biscuit shapes and colours.

Forming Mould Precision

The extruded dough is carefully pushed into a forming mould equipped with dedicated ducts and channels. This ensures precise shaping and detailing, allowing users to achieve the desired extrusion with accuracy and consistency. Whether creating intricate designs or simple shapes, the forming mould delivers exceptional results every time.

Versatile Finishing Options

Following extrusion, the resulting biscuit can undergo various finishing processes to meet specific requirements. It can be sealed on the sides using an iris shutter mould for added aesthetics or cut with a wire cutter or guillotine for precise shaping. These versatile finishing options enhance the overall quality and presentation of the biscuits, catering to diverse preferences and production needs.

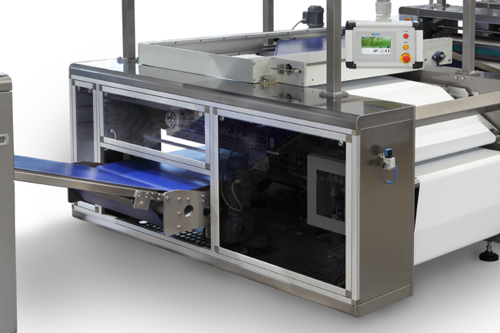

Flexible Installation Options

The extruder is typically installed above the oven, optimising space utilisation and workflow efficiency. However, for added flexibility, it can be equipped with a motorised conveyor belt to position it in front of the oven, allowing for seamless integration into different production setups. Additionally, a version of the machine with a conveyor for baking trays is available, further enhancing its versatility and suitability for various baking operations.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment