1

‘Weber Power Control’ provides intuitive operation and monitoring of parameters including performance, yield, and giveaway.

2

1.2m wide operating width/ 520mm cutting throat

3

Up to 4 track independent vario grippers/vacuum grippers

4

Up to 4 track independent vario-interleaver

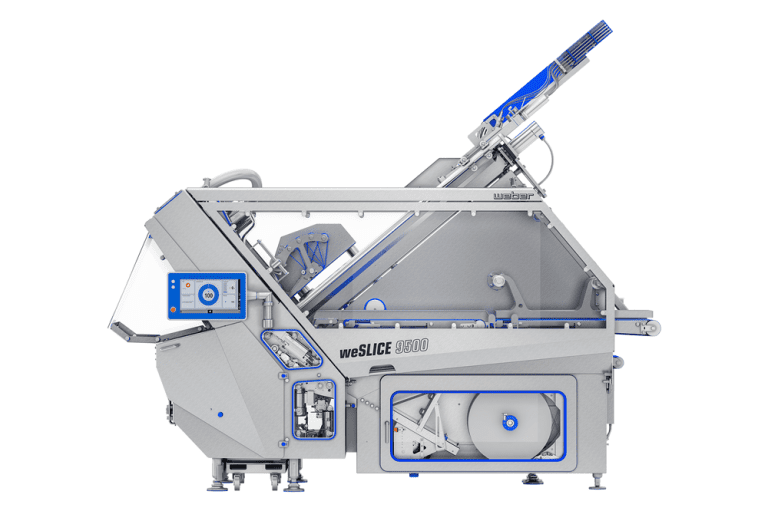

weSLICE 9500 Slicer

Weber

Designed and precision-engineered in Germany to the latest hygiene standards, the weSLICE 9500 is manufactured in compact footprint with a 520mm wide slicing throat. The weSLICE 9500 is exceptionally accurate and versatile, achieving maximum yield recovery and minimal giveaway, making it the perfect solution for cooked meats, continental meats, cheese, and natural premium products.

Precision slicing

Optimum yield

Hygienic design

Vario-interleaver and portion completion

High performance

Fast Changeovers

configurations

CCL Configuration

Slicer with integrated jump conveyors (CCU) for portioning and separate mobile transport conveyor. Slicer cutting to thickness, but with the option to retrofit a reactive check weighing or proactive scanning system.

MLC Configuration

Slicer with CCU and including checkweigher (CCW) for reactive feedback weight control. With marking conveyor for diversion of off weights / first cuts to one side for manual correction at the packing station. Proactive scanning system also available or can be retrofitted.

SLC Configuration

Machine with CCU with checkweigher and rocker system for diversion of off weights for manual correction on to an upper reject conveyor. Good portions transferred via MOV conveyor to be manually packed. Proactive scanning system also available or can be retrofitted.

RCS WPR Configuration

Slicing line with CCU, checkweigher and rocker. Including buffering and pick and place system for automatic loading of packaging machine.

MCS Configuration

Slicing line with CCU, checkweigher and rocker. Including buffering and pick and place system for automatic loading of packaging machine.

EXPERT OPINION

Tom Foran

Divisional Manager – Slicing and Packaging Line Solutions

“The Weber weSLICE 9500 Slicer can be equipped with an up to four track vacuum vario gripper and interleaver system. This machine, when incorporating the cheese specific involute blade head, offers unrivalled performance when it comes to slicing speed, capacity, end piece size and portion presentation. Contact us for more information.”

ADDITIONAL PRODUCT INFORMATION

weSLICE 9500 Slicer

Technical Data | |

|---|---|

Blade Type | Involute |

Max Slicing Speed (RPM) | 2000 |

Product Throat Height Options (mm) | 220 |

Product Throat Width (mm) | 520 |

Product Length Options (mm) | 1200 / 1600 / Endless (3200) |

Loading Type | Automatic |

Available Options |

|---|

Stacking CCU |

Waferthin CCU |

Interleaver |

SprayTech |

Folding Bar |

Idle Cut Head |

Portion Designer |

Vario Grippers |

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment

MEAT

POULTRY

FISH

CHEESE/DAIRY

PLANT-BASED

BAKERY

wePACK 7000 Thermoformer

The Weber wePACK 7000 Thermoformer is a powerful, high-performance packaging solution specifically designed for slicing applications. Engineered for safe, sustainable, and efficient packaging, it sets new standards in output, quality, and energy efficiency with advanced servo technology.

MEAT

POULTRY

FISH

CHEESE/DAIRY

PLANT-BASED

BAKERY

wePACK 4000 Thermoformer

The Weber wePACK 4000 thermoformer is a compact and flexible packaging solution. Ideal for medium production requirements, the wePACK 4000 can produce up to 100 packages per minute, making it perfect for full-range food manufacturers producing smaller batches.