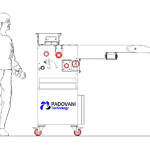

Rotary Moulding Machine RWN

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Rotary Moulding Machine RWN

Stainless steel knife hardened and ground

The rotary moulding machine features a precision-engineered hardened stainless steel knife. Its position can be easily adjusted using a knob located on the control side. The knife's movement is synchronized with the mould surface, maintaining tangency throughout the entire regulation range. Additionally, a graduated scale indicator located on the control side provides clear visibility of the knife's position.

Stainless steel scraper

For efficient cleaning, the machine includes a stainless steel scraper designed to clean the conveyor belt. Beneath the scraper, a motorised belt is positioned to collect dough scraps.

Gear motor with inverter

The main drive of the machine is powered by a gear motor with an inverter. Speed regulation is conveniently managed through the control panel located on the machine side, allowing for precise control.

Adjustable delivery nose

Designed for seamless integration with oven tunnels of varying dimensions, the machine is equipped with a delivery nose which is adjustable in height. This component features tensioning and belt centering groups, ensuring smooth delivery of biscuits to the oven.

User-friendly control panel

The machine is equipped with a control panel on the machine side, featuring a working frequency display, start/stop button, emergency button, and potentiometer for speed variation.

Optional small motorised roller

Additionally, an optional small motorised roller is available for installation on the delivery nose. This roller, equipped with its own motor and independent speed adjustment, facilitates the detachment of biscuits from the cotton belt, enhancing operational efficiency.

Code | Working Width [mm] | Installed Power * [kW] | Packaging dimensions (approx.) [mm] | Gross Weight [kg] | Max hourly production ** [kg/h] |

|---|---|---|---|---|---|

RWN 500 | 500 | 1 | 1500 x 850 x H1350 | 480 | 300 |

RWN 600 | 600 | 1,1 | 1500 x 950 x H1350 | 530 | 360 |

RWN 700 | 700 | 1,5 | 1500 x 1050 x H1350 | 600 | 420 |

Decorating Devices

Padovani Technology offers a range of decorating devices tailored for integration with their Rotary Moulding machines. From the Glazing Unit to the Sugar Sprinkler and more, these devices provide flexibility for biscuit customisation. Enhance the productivity of your biscuit manufacturing operations With Padovani Technology’s decorating devices.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment