Electric drive system via floor/overhead conveyor ensures smooth transportation

1st process chamber (smoking, cooking, etc.) is separated from the 2nd process chamber (cooling, etc.) by hinged/vertical lifting doors.

Suspended racks or installed racks/smoking carts available.

Airtight transfer zone allows total separation between low-risk and high-risk areas.

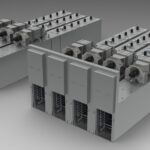

Semi-Continuous Batch System KCS

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Maurer-Atmos Semi-Continuous Batch System

The Maurer KCS has multiple possible processing systems. There is an option for drying, smoking, cooking which can be transferred to intensive cooling downstream. There are also other combinations on request. The system can also be integrated into the production area due to upstream and downstream automation.

This device is ideal for a production are as an electric drive system ensures a smooth transportation, making it easy to move around the production area with the option for floor transport, a roller or overhead rail conveyor.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment