Belt height is electrically or manually adjustable.

Afoheat pre-mix burner control allows for low energy consumption.

Easy cleaning and maintenance with removable conveyor.

Oven is fully insulated, minimising heat radiation.

Optional infrared side burners, gas flame bottom burners, and grill marking technology.

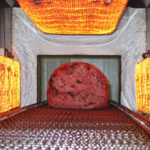

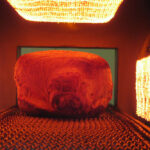

Afoheat™ Select Infrared Roaster

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Marlen Afoheat™ Select Infrared Roaster

The customisable device has a low energy consumption due to the Afoheat pre-mix burner control. Able to process raw, cooked, chilled or frozen product, the AfoFlame has minimal weight loss during its production, ensuring high-quality results. This superior hygienic design has a removable conveyor for easy cleaning and maintenance and has an optional feature of a belt brush with continuous washing systems for reduced water consumption.

With standard belt widths of 300, 600, 1000mm, there are also custom belt widths available. The machine can also be installed in line with other cooking equipment. This device is fully customisable, with an adjustable belt speed, belt height, burner power and convectional heat, the AfoHeat Infrared can be adjusted to meet any of your requirements. For maximum safety, the machine is equipped with a fat separator to prevent fires and for odour control, to ensure safety and hygiene in the production area.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment