Low energy consumption = cost savings.

Unprocessed beverages are stored in a tank.

Liquids are pressurized (rising up to 6,000 bar / 87,000 psi / 600 MPa) and pumped into the HPP tank.

Reduced TCO: Labour, production, maintenance, and energy costs are reduced.

Hiperbaric H525 / 1050 In-Bulk

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Hiperbaric H525 / 1050 In-Bulk

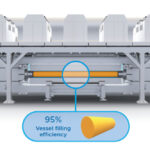

The Hiperbaric 525 / 1050 In-Bulk are equipped with new technology making the process simpler, with less steps and with a higher productivity. Its design is based on one or two vessels of 525 or 1050 litres together with a system of tanks (inlet and outlet) where beverage is temporarily stored before and after the HPP process. The unprocessed beverage fills the inlet tank which is then transferred to the processing bag inside the vessel, occupying the 90% of the total volume. Then high-pressure intensifiers will pump water to the vessel, up to 6,000 bar / 87,000 psi / 600 MPa. The pressure is kept during holding time and as soon as the pressure is released, water leaves the vessel and the already processed beverage will go to the outlet tank via sterilised pipes. With the bag completely empty, a new cycle starts. The processed beverage is now ready to be bottled in an ESL ultra-clean filling line.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment