1

Multi-functional – In-line or press centre execution.

2

Energy-efficient: Fully electric – no hydraulics, no cooling, no compressed air.

3

Ergonomic: light grid safety technology for fast manual loading.

4

Weber hygiene concept: open machine design for easy accessibility.

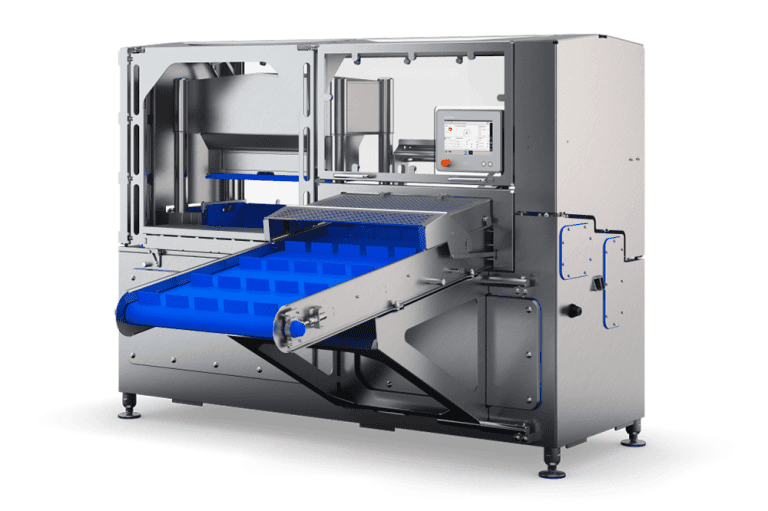

wePRESS Forming Press

Weber

The wePRESS Forming Press is the latest addition to the Weber preparation portfolio, providing precise forming of natural products for maximum slicing yield. The fully servo-driven and controlled press ensures consistent pressing quality with optimum shape to maximise slicing potential. The wePRESS gently presses the product into the required shape, fully forming corners and edges without damaging the product. The wePRESS is ideal for a variety of applications including streaky bacon, back bacon, gammon and raw ham.

Forms up to 10 products per minute (product dependant).

Fast manual loading or available with in automatic loading.

Available as a standalone unit or integrated into your existing line.

RFID die set integration, ensuring the correct die is correctly fitted every time

Compact footprint and low energy consumption.

EXPERT OPINION

Aaron Hale

Divisional Manager

“The new wePRESS Forming Press is Weber’s form press for shaping streaky bacon, back bacon, gammon and raw ham prior to slicing. Available in a variety of configurations, it integrates seamlessly into an automatic bacon production line or can be used as a stand-alone machine. Contact us for more information.”

ADDITIONAL PRODUCT INFORMATION

wePRESS Forming Press Advantages

- Available in stand-alone “press centre” execution or integrated as part of a slicing line.

- Line integration with optional Weber OneControl.

- Pressing pressure can be adjusted during the forming process depending on the process step.

- Energy-efficient: Fully electric - no hydraulics, no cooling, no compressed air.

- RFID coding of the format parts increases operational reliability.

- Easy installation and removal of the lightweight format parts for cleaning and conversion.

- Ergonomic: light grid safety technology for fast manual loading.

- Weber hygiene concept: open machine design for transparent processes - easy accessibility.

- Optional: integration of Weber Remote Service.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment