Integrated Weber PaperTech for optimised paper-based material processing

Weber control and operating technology

Servo-driven main transport chain

Special gas flushing for MAP applications reduces waste and saves resources

Accessible design for easy service and maintenance

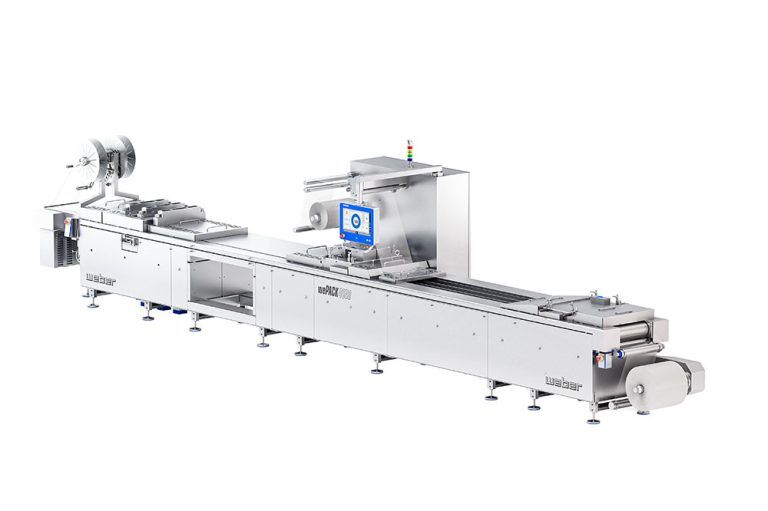

wePACK 4000 Thermoformer

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

wePACK 4000 Thermoformer

Precision and Durability

Features a roll shear cutting system for precise cutting and high-quality packages.

Reduced Material Waste

Special gassing system to minimise side trim to 20mm significantly reducing material waste by around 50%.

User-Friendly Maintenance

The thermoformer is designed for easy access, simplifying servicing and maintenance.

Flexible Film Handling

Available with standard single, dual, or jumbo bottom film rolls. Film changes are quick and convenient, thanks to a pneumatic clamping mechanism.

Reliable Servo-Drive

Ensures high-speed chain/film advance with maximum control.

4-Column Lifting Systems

Ensures perfect weight distribution for maximum reliability.

Central Lubrication

The central lubrication system ensures automatic and reliable distribution of lubricant as needed.

Versatile Film Dimensions

The film width ranges from 280mm to 560mm in 10mm increments, with a maximum advancing length of 650mm.

Flexible Package Discharge

Allows for lane-independent discharge of individual packages.

Applications

- Air

- Vacuum

- Modified Atmosphere

- Shrink

- Skinpack

- PaperTech

Technical Data | |

|---|---|

Machine length | modular; customised |

Loading area | customized |

Loading area | knee free upon Request |

Bottom film width | 280 – 560 mm, in 10 mm steps |

Top film width | up to 560 mm |

Max. index length | up to 650 mm |

Max. pack depth | up to 120 mm / 150 mm |

Performance | |

|---|---|

Cycle Speed | approx. 5 – 15 cycles/min |

Film material thickness | up to 600 mic. |

Top film reel Max diam. | 1x or 2x 400mm; 1x 500mm |

Bottom film reel Max diam. | 1x or 2x 400mm; 1x 500mm; 1x 800mm jumbo |

Reel core diam. | 3″ or 6″ cores |

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment