The quick-change roller shear cutting system automatically adjusts contact pressure to minimise downtime.

A camera system checks the top film roll against the stored recipe data to avoid the film and product loss, and increase production reliability.

Continuous data flow is maintained across the entire line with a standardised operating system.

Cross punches run slower in closed-loop operation at the start and end of cycles to minimise wear.

The system corrects bottom film deviations smoothly and accurately by detecting shifts in lane position.

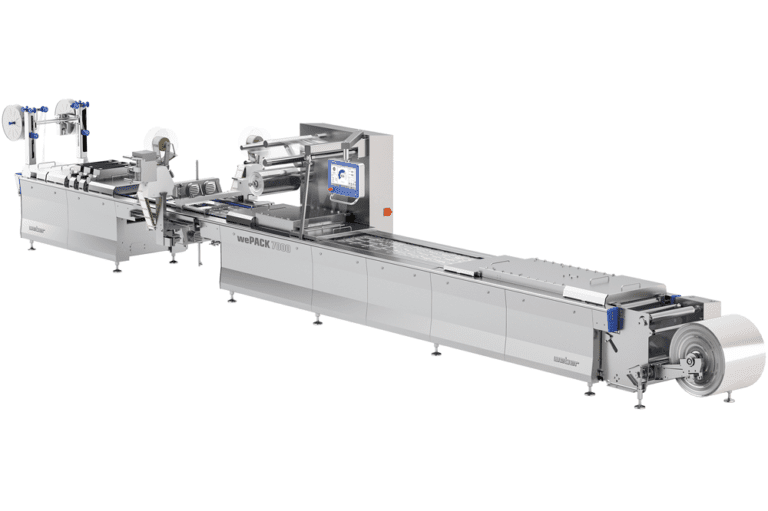

wePACK 7000 Thermoformer

SUITABLE APPLICATIONS

DOWNLOADS

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

wePACK 7000 Thermoformer

Optimal Packaging for the Highest Output Ranges

The wePACK 7000 is ideal for packaging sliced products and portions with high performance, safety, and sustainability.

Superior Process Control

Servo-drive technology ensures complete control of the cycle, providing reliable processes and short cycle times.

Weber renowned Hygienic Design

Robust, hygienic build with a 100% stainless steel design.

Reduced Wear

Cross punches operate slower at start and end cycles to minimise wear.

Accurate Film Monitoring

Camera system checks the top film roll against recipe data, preventing film and product loss while boosting production reliability.

Precise Film Adjustment

Web edge control smooths out deviations in bottom film unwinding for accurate, consistent packaging.

Peel Corner Cutting

Integrated cut for peel corners.

Fast Cutting Adjustments

Quick-change roller shear system automatically adjusts contact pressure, reducing downtime.

Optimised Processing of Fiber-based Films

Integration of Weber PaperTech technology for optimized processing of fibre-based films.

Smooth Operation

Continuous data flow across the line with a standardised operating system ensures smooth operation.

Applications

- Air

- Vacuum

- Modified Atmosphere

- Shrink

- Skinpack

- PaperTech

Technical Data | |

|---|---|

Machine length | modular; customised |

Loading area | customised |

Loading area knee free | upon request |

Bottom film width | up to 660 mm |

Top film width | up to 660 mm |

Max. index length | up to 1.500 mm |

Max. pack depth | up to 80 mm without / 65 mm with top lift |

Tool top lift forming / sealing | Yes / Yes |

Performance | |

|---|---|

Cycle Speed | approx. 4 – 17 cycles/min |

Film material thickness | up to 1.200 mic. |

Top film reel Max diam. | 1x or 2x 500mm; 1x 1.000mm |

Bottom film reel Max diam. | 1x or 2x 500mm; 1x 1.000mm jumbo (800 mm for belt loader) |

Reel core diam. | 3″ or 6″ cores |

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment