Rotary Cutting Machine

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

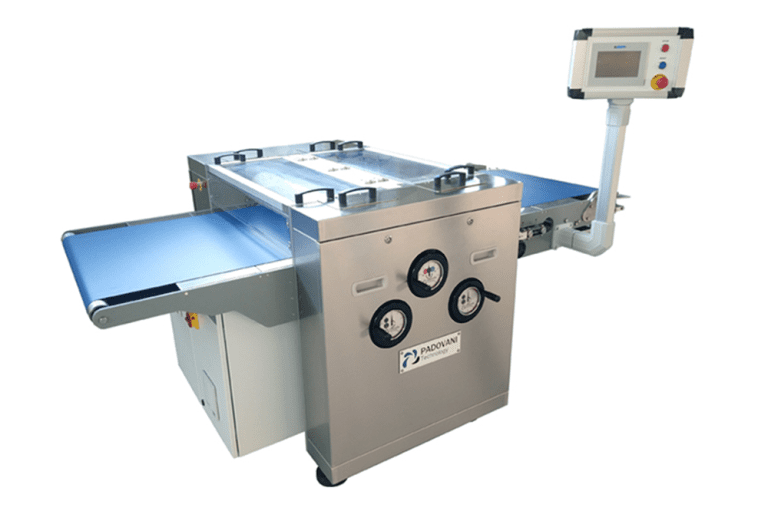

Padovani Technology Rotary Cutting Machine

Print & Cut Functionality

The Rotary Cutting Machine simplifies the process of adding intricate designs to your biscuits by integrating embossing and cutting capabilities. This ensures that each biscuit is enhanced with precise graphics, enhancing consistency and quality across every batch. With this functionality, you can effortlessly create visually appealing biscuits that meet the highest standards.

Versatile Design Options

Tailor your biscuit production process to your specific needs with the Rotary Cutting Machine's versatile design options. Choose between a "single roller" configuration, which combines embossing and cutting functions into one roller, or opt for a "double roller" setup for greater flexibility in adjusting dough sheet thickness and achieving clearer embossing results. This adaptability allows you to customise your biscuits according to your desired specifications, ensuring maximum versatility in your production line.

High Precision Synchronisation

Benefit from the Rotary Cutting Machine's high-precision mechanical system, which synchronises the movement of its two rollers with exceptional accuracy. This synchronisation ensures optimal positioning of biscuit graphics during embossing and precise cutting, resulting in consistently well-defined shapes and designs. With this level of precision, you can confidently produce biscuits of uniform quality that meet your exacting standards..

Specialised Configurations

Customise your Rotary Cutting Machine to accommodate specialised biscuit configurations, such as those with inner holes such as pretzel shapes. The machine offers a dedicated system for recovering central dough, allowing you to create a diverse range of biscuit designs with ease. This specialised configuration enhances the versatility of your production capabilities, enabling you to meet the unique demands of your customers.

Efficient Scrap Management

Streamline your biscuit production process with the Rotary Cutting Machine's efficient scrap management system. After cutting, a conveyor belt system swiftly separates biscuits from scrap dough, ensuring minimal wastage and maximising efficiency. The scrap dough is redirected to the forming hopper, minimising downtime and optimising production throughput.

Convenient Delivery System

Ensure smooth transition and consistent baking results with the Rotary Cutting Machine's convenient delivery system. Biscuits are seamlessly conveyed to the oven via a delivery bridge, minimising handling and ensuring uniform baking.

Code | Working width [mm] | Power* approx. [kW] | Packaging dimensions (approx.) [mm] | Gross weight (approx.) [kg] | Diam. cylinders [mm] |

|---|---|---|---|---|---|

RCM 2-600 | 600 | 3 kW | 2100 x 2400 x H 2200 | 600 | 120 / 180 |

RCM 2-800 | 800 | 3 KW | 2200 x 2400 x H 2200 | 700 | 120 / 180 |

RCM 2-1000 | 1000 | 3 KW | 2500 x 2400 x H 2200 | 850 | 120 / 180 |

RCM 2-1200 | 1200 | 4 kW | 2700 x 2400 x H 2200 | 1000 | 120 / 180 |

* Power determinable as a function of the oven length and of the cooking time.

ENQUIRY

Contact us for more information on this or any other product we offer.

Related equipment