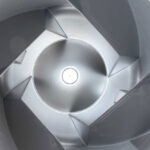

Large drum capacity with filling volume of 60%

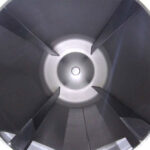

Construction of fins allows a gentle or intensive tumbling action

Parameters are programmable with the user-friendly touch panel

Tumbler Type R

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Henneken Tumbler Type R

Henneken is a manufacturer at the leading edge of tumbling technology, whose design and build quality is second-to-none. Continuous development of standard or in-line models, offering unique fin or helix design, with tipper or vacuum loading, has resulted in a comprehensive range of solutions for any given application.

Whether you are producing small or industrial-scale batches, our range of tumblers can accommodate any size capacity requirement with 50 – 12,000 litre volumes available and a comprehensive range of options, including:

- Glycol jackets for keeping product at an optimal temperature during the cycle, ensuring consistent results

- Weigh cells for constant monitoring of product and additive ratios

- Different loading solutions for 200/300 litre stainless steel bins and 500 litre plastic boxes, as well as vacuum options, for minimal handling

- Tumblers which can also be used for defrosting, straight through to a continuous tumbling cycle

Backed by Interfood’s full technical and service support, our range of tumbling solutions can be integrated into your existing production line or supplied as part of a comprehensive line solution in conjunction with our wide range of preparation equipment.

ENQUIRY