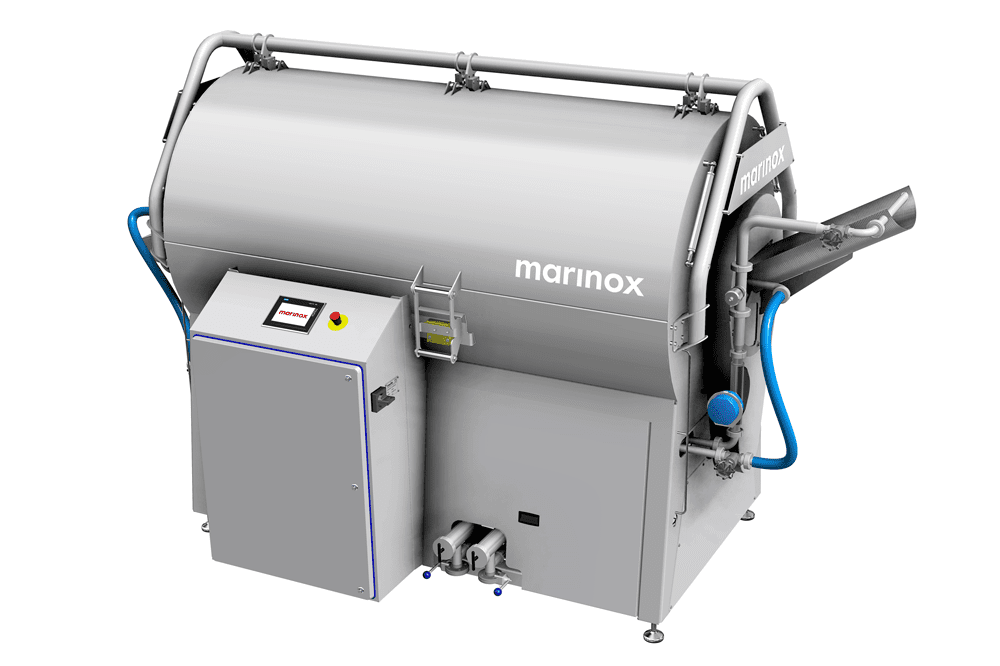

DK950 Drum Cooker

SUITABLE APPLICATIONS

DOWNLOADS

DK950 COOKING AND COOLING SOLUTION

Infeed conveyor

Drum Cooker DK950

Vibration feeder – Cooker to

Cooler

Drum cooler with ice water

Vibration conveyor for drainage

incl. drip-oiling

Ascending conveyor to scale

EXPERT OPINION

ADDITIONAL PRODUCT INFORMATION

Marinox DK950 Continuous Cooker

The DK950 drum cooker enables continuous cooking of pourable food. The DK950 is available as a free-standing unit or can be integrated into an entire cooking line.

The modern cooker is user-friendly and easy to operate. Due to clear graphical visualization on the control panel, recipes and parameters can be quickly adjusted. The DK950 meets the ecological and quality requirements of modern food production. It convinces with double-walled, insulated construction and built-in sensor technology for checking the cooking water quality. The consumption of fresh and process water can thus be efficiently matched to the cooking process and the products to be processed. Overcooked or undercooked products are eliminated by the sophisticated design of the system, as is product loss within the system.

The patented product discharge makes it possible to continue processing with a constant flow of products after the cooker. The very compact design also allows the achievable production output to be realised in the smallest possible space.

Have the possibilities of batch production been exhausted? The unique price/performance ratio of the DK950 makes it possible to expand production even in the smallest of spaces with a clearly calculable investment.

| DK950 Drum Cooker | |

|---|---|

| Hourly capacity | Approx. 250 - 400kg dry pasta, with 10 minutes cooking time |

| Drum diameter | 950mm |

| Cooking time | Variable from 3 to 60 minutes |

| Heating type | Electrical or steam |

ENQUIRY