“Hygienic Secure” range of industrial bowl cutters impresses with innovative details

Equipped with innovative ideas for constant optimisation of safety, hygiene, operational processes and consistent user orientation, the range of machines from innovation-leader K+G Wetter make a significant difference in food processing while ensuring sustainable added safety and efficiency. The “Hygienic Secure” range of industrial bowl cutters combines the reliable and proven quality that K+G Wetter is recognised for, with the modern requirements of food processing. This has been further recognised with the silver International FoodTech Award 2021. The DLG (Deutsche Landwirtschafts-Gesellschaft – German Agricultural Society) and its partners have been honouring pioneering developments in innovation, sustainability, and efficiency in the field of food technology with this award for many years, with an international jury of experts awarding prizes for progressive concepts.

“Receiving the silver International FoodTech Award 2021 fills us with pride,” emphasises Sales Manager, Volker Schlosser. “We work every day and with great passion to constantly optimise our machines. So we are particularly pleased that our efforts have been rewarded with the award and we start the new year highly motivated.”

K+G Wetter solutions are designed by experts with optimum operator working practices and requirements in mind. True to the principle: From practical experience for practical use. It is precisely this high level of user orientation that characterises their solutions and makes the difference. “Through our industry contacts in the industry and constant exchange with them, we always know exactly what is important. This is precisely where we come in with our developments in engineering and process technology,” says Volker Schlosser. “Our solutions are designed to meet the daily requirements of our customers’ operations. The fact that our machines are easy to operate, ergonomic and above all hygienically safe is a priority,” says Schlosser.

The cleverly thought-out and user-oriented details make the difference: The industrial vacuum bowl cutters of the “Hygienic Secure” range set new standards in terms of efficiency, safety and hygiene.

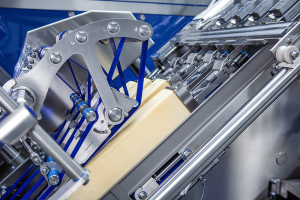

Innovative knife cover strip can be clipped in and out without tools

The new knife cover strip is a unique worldwide highlight in terms of hygiene. The knife cover strip is self-adjusting and can be easily clipped in and out without tools for cleaning. Cleaning is effortless and there are no concealed corners where deposits could form. Since it is easy to visually check the cleaning success, contamination from residues is thus eliminated.

Volker Schlosser: “In addition to being safe and easy to dismantle for cleaning, the knife cover strip can absorb any frictional resistance that occurs thanks to its vertical movement capability. This is how we counteract possible abrasion. There is no comparable solution in the world for securing an otherwise so sensitive spot on bowl cutters.” This unique solution further convinced the jury of the International FoodTech Award.

A special advantage of the “Hygienic Secure” machine generation

The area between the cutter bowl and the vacuum chamber does not need a seal at all, making replacement, wear, and risks of contamination a thing of the past. In addition, there are large cleaning flaps in the vacuum vessel that can be opened without tools- allowing easy access with the cleaning lance. The visual inspection of the cleaning results can therefore be carried out safely, quickly and reliably. Hygiene and product safety are guaranteed by the simple and hygienically reliable cleaning.

Simple and reliable cleaning: Easily accessible cleaning flaps enable simple and hygienically safe cleaning. This saves time and money and ensures products of the highest quality.

Other features such as the new highly efficient cooking system, the tool-free removal of various necessary parts such as the bowl wiper, bowl support pad or the newly developed silencer for significant noise reduction when using vacuum were further features that convinced the jury. The result is unrestricted process safety and efficiency as well as first-class quality products.

K+G Wetter is a global partner of choice when it comes to manufacturing high-quality, reliable meat-processing machinery. K+G Wetter develops advanced cutters, grinders and mixers for butchers and skilled workers in the meat-processing trade and industry. The company’s sophisticated technology and high-quality processing mean that machines from K+G Wetter contribute significantly to customers’ business success. As a world-famous brand, the company from the Breidenstein district of Biedenkopf, in the German State of Hesse, supports its customers with personal and individual advice.

The K+G Wetter range is exclusively available in the UK and Ireland from Interfood Technology’s dedicated Preparation Division.

© K+G Wetter

Via: https://kgwetter.de/